Trade Products_COAL - The Most Significant Source for Power Generation

COAL is the most readily available natural resource that is in abundance and an extremely cost effective source of energy.

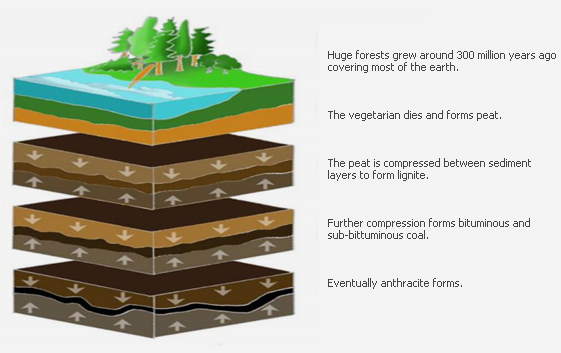

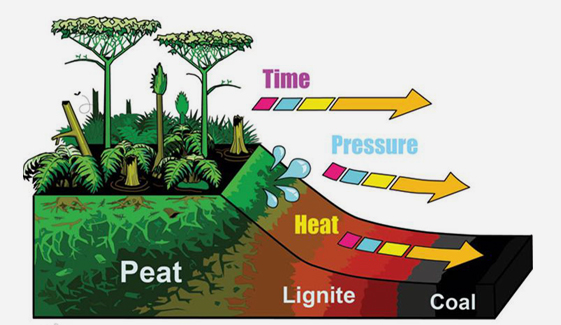

High Rank Coal : Bituminous, Anthracite (High Energy Content

& Low Moisture)

Low Rank Coal : Peat, Lignite, Sub-bituminous (Low Energy Content

& High Moisture)

| Low Rank Coal |  |

|

| 1. | Brownish-black in colour and has a carbon content of around 25-35%, a high inherent moisture content sometimes as high as 66% | |

| 2. | Low energy density and typically high moisture content. Unfortunately its high moisture content and susceptibility to spontaneous combustion it can cause problems in transportation and storage. | |

| 3. | Low heating value, high handling cost and spontaneous combustion but contain low sulfur and low ash contents . | |

| Potential of Low Rank Coal | ||

| 1. | Low rank coal can be efficiently and economically processed to yield a higher-grade and higher heating value. | |

| 2. | Enormous increase and economic benefit on the energy supply. | |

| 3. | Reducing Environmental impact | |

| Coal Enhancement has to be | ||

| 1. | Economical | |

| 2. | Address the issues of Spontaneous combustion | |

| 3. | Reducing Moisture permanently | |

Expenergy Technology

| 1. | Enhancing the calorific value of the low grade

coal by reducing the moisture content. |

|

| 2. | TM reduced to near IM level. | |

| 3. | Minimal equipment needed. |

|

| 4. | Fast set up time. |

|

| 5. | Low cost and high margin. |

|

Market Comparisons |

|||

Kobe Steel –

UBC (Japan) |

White Energy –

(Australia) |

Expert Energy |

|

600 MT/day demonstration plant was constructed and

testing for commercial use |

1 million MT / annum commercial plant has been constructed

in East Kalimantan, Indonesia |

||

| Effect | Increase Calorific Value Reduce Moisture |

Increase Calorific Value Reduce Moisture Higher Density |

Increase Calorific Value Reduce Moisture |

| Raw Feed | Coal pulverized, powder up to 60 mesh |

Coal pulverized, powder up to 60 mesh |

Coal crush 1 to 5 cm |

| Power / Energy Requirements | Must have power plant, for 1 million ton needs approx.

6 – 10 MW |

Must have power plant, for 1 million ton needs approx.

6 – 10 MW |

N/A |

| Coal Final Product | TM: 12-15% Calorific Value AR: 5,800 – 6,500 HGI: depend on briquette system |

TM 12-15% Calorific Value AR: 5,800 – 6,100 HGI: depend on briquette system |

TM 11-15% Calorific Value AR: 5,000 – 5,500 HGI: stable |

| Production Capacity | Depends on briquette machine capacity, installation

time approx. 30 months |

Depends on briquette machine capacity, installation

time approx. 2 years |

Unlimited capacity. Rotary System, installation time

approx. 1 – 2 months |

| Processed Product | Coal Briquette |

Coal Briquette |

Similar to Raw coal |

| Operation Cost | About US$ 10 – 15 per ton |

About US$ 10 – 15 per ton |

About US$ 7 – 9 per ton |

| CAPEX | Approx. US$ 100M – US$ 150M for a 1 million

ton capacity plant |

Over US$ 60M for a 1 million ton capacity plant |

US$ 3M-6M for a 1 million ton capacity plant |

| Upgrading Process Time | Slow |

Slow |

Fast |